September 2025

Behind-the-scenes look at sheep shearing

When you put on that beautiful sweater hanging in your closet, do you ever wonder where the wool comes from? No? Well, I must confess, neither do I.

When I heard that the sheep on the farm where we are currently staying were going to be sheared, I asked the farmer if I could see how it was done.

Question: Why is it necessary to shear sheep?

The shearing of sheep is not only important for wool production, but also for the welfare of the animals. It keeps them healthy, prevents overheating, and ensures high-quality wool. Andries, the farmer on the farm where we stay, told me that shearing is usually done once a year. According to farming magazines (which I read online), this ensures that the animals stay comfortable while farmers collect wool for textiles and other industries.

Workers busy in the shearing shed

Woolly sheep are waiting their turn to be sheared

The sheep shearers are not workers of the farm, and their only job is to go from farm to farm to shear all the farmers’ sheep. It’s quite impressive to see how comfortably and quickly they shear the sheep. One of the men sheared a big sheep in only 2 minutes, while a lamb was done in one minute and 30 seconds.

Shearer in action

Sometimes the sheep lie down and other times they sit upright

To do this job, you need to know how to hold and shear a sheep at the same time

Long steady strokes close to the sheep’s skin help remove wool efficiently without harming the sheep. This creates a single fleece that can be rolled up for processing.

The fleece is sheared off in one piece

The permanent farm workers lend a hand to ensure that everything runs like a well-oiled machine. While the sheep shearers focus solely on the sheep, there are two workers who are constantly sweeping away the loose pieces of wool with a broom so that the area where the sheep are being sheared can remain clean at all times.

Ricardo constantly gathers up all the loose wool

The sheep are kept together until everyone has been sheared, after which a door is opened, and they then run outside.

Sheared and unsheared sheep

Once the fleece is removed, it is shaken free of debris, weighed and then prepared for grading.

Scale to weigh the sheep’s fleece

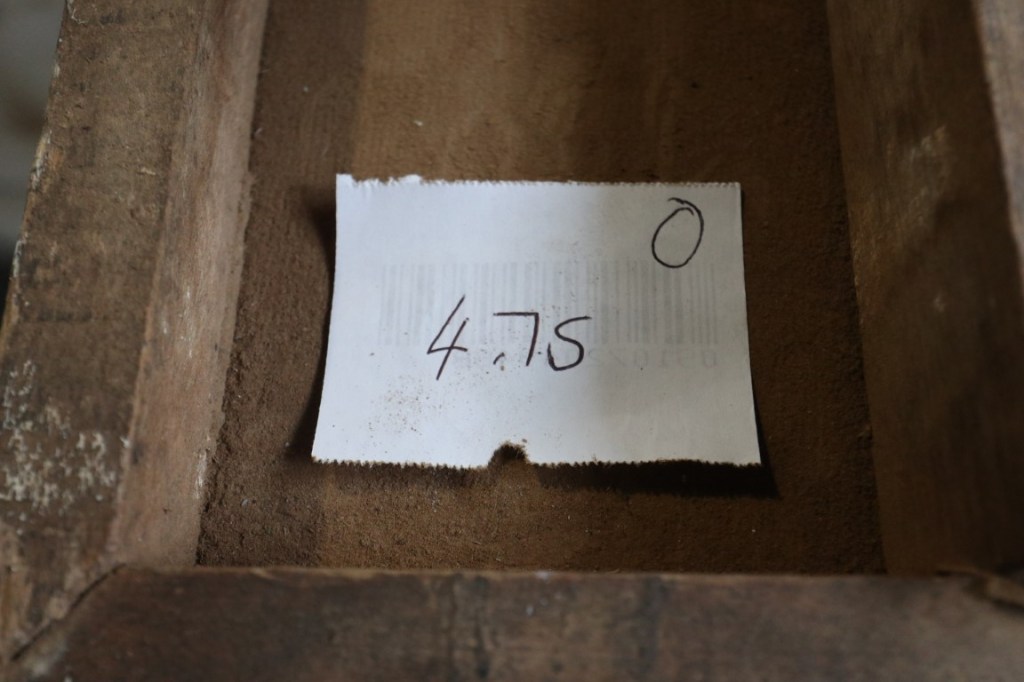

Every sheep has a tag in its ear, which makes it easier to record data and track individual sheep. Before each sheep is sheared, Andries scans the tag and then Rachel prints a barcode indicating the weight of the fleece. The average weight of a sheep’s fleece is between 4kg – 5kg.

Rachel and one of the sheep shearers’ helpers weigh the fleece

Tag inside sheep’s ear

Barcode and weight of one sheep’s fleece

The fleece that has been sheared are folded in a certain way so that it can be thrown open on the wool handling table in one motion for the grading process to begin.

Folded sheared fleece

Sheared fleece thrown open on the table

The sheep shearers’ team have a classifier and skirter who remove all skirting/edge trimming and double-cut wool (this wool is handed over to the pieces table). The fleece is then divided by the classifier and skirter on the fleece lines and placed into wool bins.

Classifier and skirter busy working on the sheared fleece

Wool bins

At the pieces table, the skirting and double-cut wool, as well as urine-stained wool, dirty wool and pieces are sorted. This is also the table where the permanent farm workers are stationed.

Farm workers, Adam and Richard, at the pieces table

Richard sorts through pieces of wool

The filled wool bins are now taken to the wool press where the men are required to jump/tramp the butts by stomping on the wool and pushing it down. This is repeated each time the butt appears full, until the top corners of the butt are tight and it can be packed into bales that will later be sold. The wool press is also manned by two of the permanent farm workers.

Wool at the wool press

Ballie and Eugene working at the wool press

Filling the butt until it’s full

Wool bales (compressed wool)

As mentioned earlier, once all the sheep in one group have been sheared, a door is opened so that they can go outside. Andries stands inside with the sheep and two men outside, and then each count how many sheep there are. It was fascinating that all three men ended up with the same number every time – all of this happens within a minute. I also tried to count but had to stop after 5 sheep because I lost track. (I suspect I won’t be asked to help with this particular task anytime soon).

Sheared sheep getting ready to leave the shed

1, 2, 3, 4, 5 … oh, hang on …

The last few sheared sheep on their way out

With a well-deserved break, before the next flock of sheep shows up for their ‘haircut’, it is time for the sheep shearers to put new combs and cutters on their electric clippers.

Sheep shearers getting ready (left) and their clippers

Everybody is taking a break

When I left the shearing shed, I walked over to the field where I saw unsheared and sheared sheep. The whole process of shearing sheep is definitely hard work, and I think I will perhaps appreciate my sweater more the next time I wear it.

Are we next?

Fabulous, bare and maybe even slightly offended by the breeze

A few weeks after the sheep were sheared, a large truck arrived at the farm to load the bales so that they could be taken to Gqeberha (previously known as Port Elizabeth) where it could be auctioned.

Wool bales ready to be transported and auctioned

Marthinus and Joos (left) and Adam and Richard (right)

Loading bales on a forklift

Loading the bales on the truck

All the bales loaded and ready to leave the farm

Richard, Marthinus, Adam, Eugene, Ricardo and the truck driver

A beautiful thought on the truck

The farm’s sheep wool on its way to being turned into beautiful sweaters

As the wool heads off to its next chapter, I’m left with a heart full of farm stories (and even the sheep blink in disbelief). Thanks for joining me – until next time, may your days be fleecy and full of wonder.

Thank you for sharing this, it’s very interesting. It’s quite a process, which I hadn’t thought of before, so much more work goes into it, before even starting making woollen clothes, and even balls of wool for knitting!

LikeLiked by 1 person

My mum, who grew up on a farm, always told me what a labour-intensive process it is to shear sheep … and she was not wrong! Absolutely, sheep shearing is just the first step in making wool – I now understand why some high-quality sweaters are so expensive!

LikeLiked by 1 person

It’s a fascinating process, Corna. Amazing how the fleece remains whole. Like peeling a potato all in one go. I can never do that, and spuds don’t wriggle! I expected the wool to be washed or cleaned at some stage so interesting to see that it doesn’t happen on the farm xx

LikeLiked by 1 person

I really enjoyed watching this whole process unfold. I think that washing and preparing the sheep’s wool is an entirely new phase (and probably also very time-consuming, which the farm doesn’t have time for because they also focus on other products). Haha 😁, I agree with you peeling the potato … it seems neither you nor I will make good sheep shearers!

LikeLiked by 1 person

Very Interesting as I watch the sheep shearing competitions each summer at the Great Yorkshire Show which attracts shearers from far and wide but I’ve never seen it take place on a farm. In the UK most of the wool just goes for filling mattresses, etc and not for knitting which is a pity. Do you knit? My mum and grandma were keen knitters but I was pretty useless and gave up.

LikeLiked by 1 person

Oh yes Marion, I remember that you had previously written about sheep shearing. It was very interesting to experience it myself now, especially how it’s done on a farm. My mum has tried to teach me countless times how to knit (she is very good at that), but I suppose – like you – I’ll have to admit that I’m hopeless with knitting needles in my hands 😉.

LikeLiked by 1 person

Thanks for sharing this, Corna. I will definitely appreciate all the work involved next time I put on a sweater.

LikeLiked by 1 person

Thank you, Tricia. I don’t always think about how much work goes into my beautiful sweaters … this was a bit of an eye-opener for me 😊.

LikeLiked by 1 person

This was so interesting! I knew that wool comes from sheep, but I never thought about all the individual steps in the process or the precision that’s required. I also can’t imagine walking around with 4-5 kg of fleece attached to me. That’s so much!

LikeLiked by 1 person

You’re right Diana, I also look at my sweater differently after watching the whole shearing process. 😁 I had to laugh at your comment about the 4-5kg of fleece you’d have to walk around with if you were a sheep … it can’t be too comfortable, right? But on the other hand, after the sheep were sheared, they look so ‘naked’ – I wonder what they would prefer?

LikeLiked by 1 person

I imagine it would depend on the weather?

LikeLiked by 1 person

Probably yes. Maybe it doesn’t really matter for the sheep to be sheared, because it’s done during spring when winter are over and the warmer summer months are ahead.

LikeLiked by 1 person

What an interesting read. It is incredible how quickly those shearers do their job so expertly. Also team work is dream work with everyone knowing exactly what they need to do. Yes – fresh appreciation for the end product that appears magically in the shop.

LikeLiked by 1 person

Yes, a wriggly sheep is definitely not easy to handle … but the shearers make it look like a picnic 😉. It was wonderful to see everyone doing their part and to see how the end product leaving the farm (while the guys looked quite proud of their work). I now look at the sweaters in the stores with new admiration!

LikeLiked by 1 person

I’ve seen sheep sheared here in the UK but never had a glimpse of what happens to the fleeces immediately afterwards. Like you I’m always impressed by the speed with which the shearers work, and always without cutting the sheep (which I’m sure is what would happen if anyone were every silly enough to let me have a go!)

LikeLiked by 1 person

I know better than to get involved in shearing sheep (it won’t end well) 😉. And that’s exactly why it was so amazing to see how quickly a sheep can be sheared – it probably comes with years of practice too.

LikeLiked by 1 person

Some people I know own a farm with a very small flock of sheep so I learned about shearing and skirting from them. I think you need a strong back and a good technique to be a shearer. They make it look easy but it is quite a skill. Then getting the wool sorted out and processed is another long process, so yes, I too appreciate wool far more now!

LikeLiked by 1 person

Oh yes, I agree with you – definitely a strong back and skilled in their job! I can’t imagine how these shearers must feel after having to shear sheep for months on end! I washed my sweaters and stored them for next year’s winter … and when I put them on again, I will make sure to remember why some sweaters are so expensive!

LikeLike

I spent a year travelling NZ and Australia after university. We stayed on a farm next to a sheep farm for a couple of months and ended up ‘working’ for them during sheep shearing season. They taught the different positions to use to keep the sheep calm while they were sheared and then let us shear one each! It was very fun, but very stressful. I felt bad for the poor sheep since it took me so long. I appreciate wool ever since. Maggie

LikeLiked by 1 person

I remember how many sheep there were in NZ when we were there in 2019 (someone told us back then that there are between 10-20 sheep for every person living in NZ 🙈). I think I would be useless at shearing a sheep (my sheep would all be super stressed if I had to shear them). It’s amazing that you had the opportunity to shear sheep – as they say: Been there, done that!

LikeLiked by 1 person

What an interesting process! Those fleeces are so thick!! The amount of steps the wool has to go through until it’s a saleable garment is nothing short of impressive.

LikeLiked by 1 person

That’s true Hannah, those fleeces are incredibly thick – their own sweaters to keep them warm in winter 😉 (that’s probably why they are only sheared in Spring). I was very surprised to see how many steps the wool has to go through on the farm … just think how many more processes it has to go through before it can be turned into sweaters.

LikeLike

I imagine it would be neat to see a sheep being sheared. It’s wild to hear that it only takes about 2 minutes to shear an adult sheep. The sorting sounds like it would be time consuming. Thanks for documenting the process.

LikeLiked by 1 person

I’m glad that you also found the process of sheep shearing interesting, Linda. Watching how quickly those guys shear the sheep was quite amazing … they clearly know what they are doing (I was really surprised at how obedient the sheep were throughout the whole process – they were probably happy to get rid of the excess wool 😉).

LikeLike

Excuse me Corna, if I can’t get excited about this post. Being a farmer’s daughter (boerer maisie??) I’ve been in more shearing sheds than I’ve had hot dinners!! 🙂 🙂 Glad you enjoyed the process though. Mel

LikeLiked by 1 person

I didn’t know you’re a ‘boere meisie’ (I love that you know the Afrikaans word – even though the spelling is a bit “different” 😁). And I completely understand why sheep shearing doesn’t interest you at all!

LikeLiked by 1 person

🙂 – sorry, I should have Googled the correct spelling! Have a happy week. Mel

LikeLiked by 1 person

Well, the fact that you could type this without Google is even more admirable! Happy week to you too Mel 😊.

LikeLiked by 1 person

🙂

LikeLiked by 1 person

I saw one sheared once, but this is quite an operation! Quite amazing they can do all that without harming the sheep. I guess it’s like a buzz haircut. How interesting to see how they process all that wool once its taken off.

LikeLiked by 1 person

As you say, Ruth, it is a long and intense process to shear a sheep … and one must also bear in mind that the wool still needs to be processed after this into sweaters/carpets/etc. 🤔. It was good to see that the sheep did not get hurt during the shearing – probably thanks to the men who are so skilled with the equipment!

LikeLiked by 1 person

Thank you for sharing how the wool process starts out, I found it so fascinating. They must get a lot of money for the wool to be able to pay the people to shear and prepare the wool before shipping it out.

LikeLiked by 1 person

It was a very interesting process to witness – with our hot summer days now starting, I think the sheep are quite happy to be rid of a lot of their wool 😉. I’m not sure that the farm gets paid so much for the wool – there’s a middleman who probably gets more money than the farmer (that’s unfortunately how it usually works). But I’m sure it covers the costs of the shearers and hopefully also a slight profit that can be reinvested in the farm.

LikeLiked by 1 person

Thank you for this.

LikeLiked by 1 person

I’m glad you enjoyed the post. Our farmers and their workers do such an important job, and it was nice to be able to see how skilled they are.

LikeLike